Radiographic (RT) Crack Evaluation System

OmnixOne developed an AI-powered system to evaluate and classify cracks in gamma-ray RT images. The system assesses crack size, depth, damage levels, and location, enabling data-driven maintenance and repair decisions.

Client Requirements

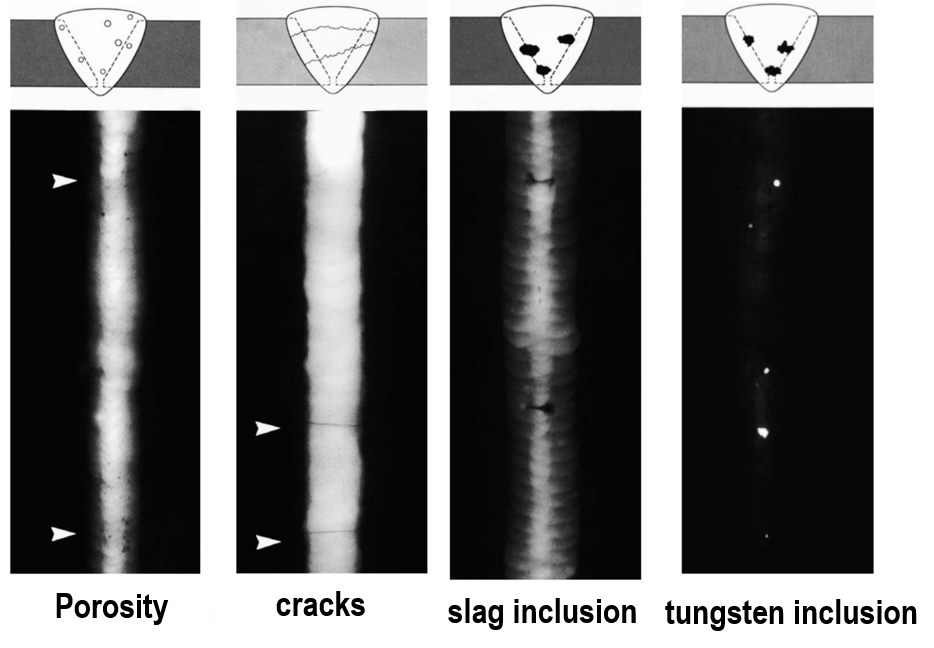

The client provided annotated gamma-ray RT images of various materials to detect and classify cracks using advanced AI/ML techniques.

Imaging Technique

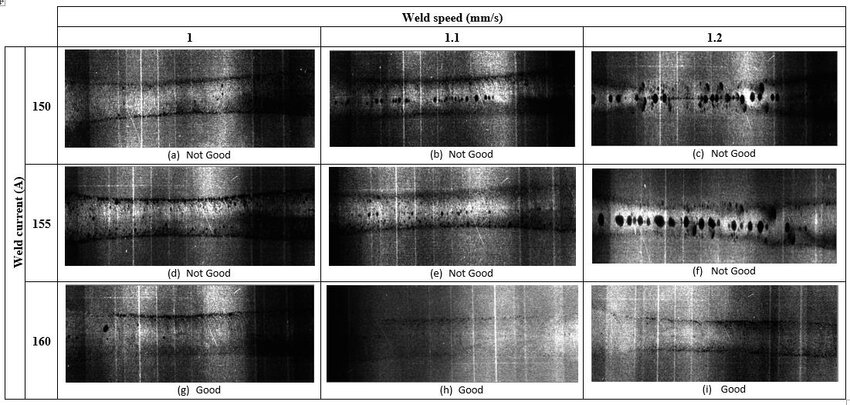

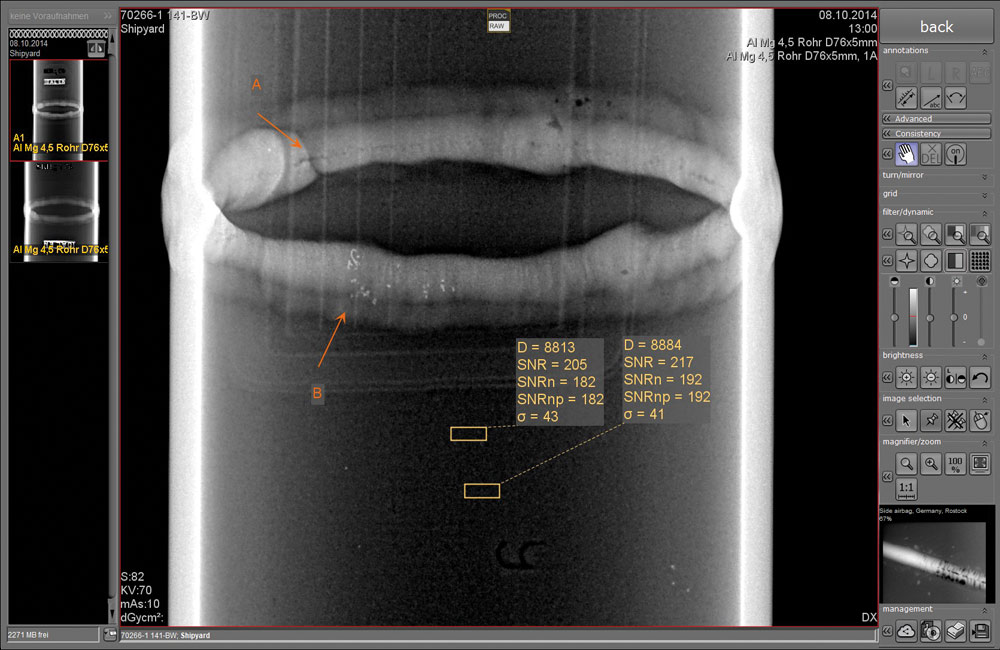

Utilized gamma-ray radiography, a non-destructive testing (NDT) technique, to capture images of pipeline structures. Gamma-ray RT is ideal for thick materials, providing insights into internal flaws like cracks and weld defects.

Technical Approach

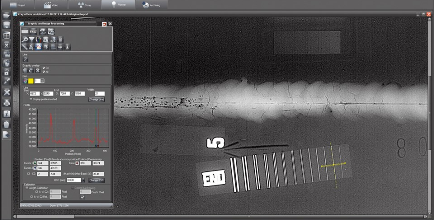

- Image Preprocessing: Used OpenCV for denoising and enhancing image contrast to address the noisier and lower-contrast nature of gamma-ray RT images.

- Data Augmentation: Applied rotation, flipping, and scaling to diversify the dataset and improve model robustness.

- Segmentation: Tested U-Net and Mask R-CNN, ultimately using U-Net for its lightweight compatibility and effectiveness in identifying faint, irregular crack lines.

- Damage Classification: Classified damage using ResNet into three levels based on crack severity.

Damage Level Classification

- Urgent Repair - Immediate attention required.

- Moderate Concern - Requires monitoring.

- Low Concern - No immediate action needed.

Crack Location Identification

Accurate identification of crack locations on pipes using image reference points.